目录

ToggleSmall and medium-sized enterprises face increasing pressure to increase productivity, maintain consistent product quality, and reduce operating costs. One of the most effective ways to achieve these goals is to introduce automated equipment, such as bottle filling and capping machines.

Traditionally, many SMEs relied heavily on manual labor for bottle filling and capping, which is time-consuming and prone to errors. With technological advances, even small businesses can now benefit from automated solutions once available only to large factories.

1. Understanding Bottle Filling and Capping Machines

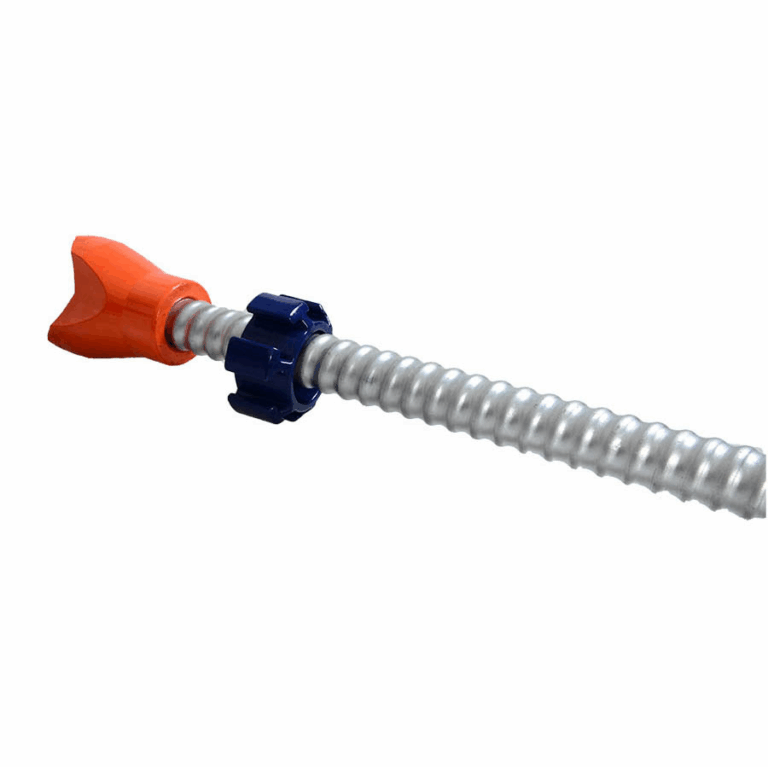

- Bottle filling and capping machinesare specialized equipment used to automatically dispense liquids or semi-liquids into bottles and then seal them with caps.

- Depending on the model, these machines can handle a wide variety of products, including beverages (water, juice, milk, soft drinks), cooking oils and sauces, liquid detergents and cleaners, and cosmetics.

- For SMEs, the machines are typically compact, cost-effective, and easy to operate, ensuring they can fit even within limited production spaces without requiring major layout adjustments.

2. Advantages of Bottle Filling and Capping Machines in Small and Medium-Sized Production Lines

- They can improve efficiency. Manual bottling can take hours and produce inconsistent output. A filling and capping machine can process dozens or even hundreds of bottles per hour, significantly reducing cycle time. This means small and medium-sized enterprises can fulfill larger orders without increasing labor costs.

- Maintaining consistent quality. Consistent product filling and capping is critical to brand reputation. Automated systems ensure precise liquid amounts and secure capping, reducing leaks, spills, or underfilled bottles.

- Sauces save on production costs. While the initial investment may seem high, small and medium-sized enterprises can quickly recoup their costs through reduced labor costs, reduced waste, and increased production capacity.

- As demand grows, small and medium-sized enterprises can easily expand their operations by upgrading their filling and capping machines or integrating other equipment into their production lines.

3. Key Applications of Bottle Filling and Capping Machines for Small and Medium-Sized Enterprises

Small juice producers, craft breweries, and bottled water suppliers benefit from automated filling and capping technology, enabling them to meet market demand while maintaining product freshness and hygiene.

- Producers of sauces, cooking oils, and condiments often handle viscous liquids. Professional filling and capping machines ensure clean, accurate filling, preventing product loss.

- In the cosmetics and daily necessities industries, hygiene and precision are paramount. Machines ensure precise dosing and tamper-evident seals, which are crucial for consumer safety and regulatory compliance.

For detergents, disinfectants, and liquid soaps, automated bottling ensures consistent product appearance and reduces human exposure to potentially harsh chemicals.

4. Key Considerations for Selecting an SME-Friendly Bottle Filling and Capping Machine

When selecting a bottle filling and capping machine for a small or medium-sized production line, key features include: a compact design that can be installed within a limited footprint without disrupting workflow; adjustable fill volumes to accommodate different bottle sizes and liquid types.

Easy maintenance, minimizing downtime for cleaning and maintenance; energy-saving, reduced electricity consumption, and cost savings; user-friendly controls for quick adjustments and reduced operator training; durable stainless steel and food-grade materials ensure long equipment life and compliance with hygiene standards.

5. Integration of Bottle Filling and Capping Machines into Existing Production Lines

SMEs typically use a mix of manual and semi-automatic processes. Integration of a bottle filling and capping machine involves:

- evaluating the current workflow to identify bottlenecks and areas where automation technology could provide the greatest benefit; s

- pace planning to ensure the machine can fit within the existing space and does not interfere with other operations;

- operator training to train employees to effectively operate and maintain the machine; and trial runs to test the machine with actual products and fine-tune settings.

6. Maintenance and Lifespan of Bottle Filling and Capping Machines

For small and medium-sized enterprises, machine lifespan is a crucial factor in the investment decision. Regular cleaning, lubrication, and part inspection will extend the lifespan of a bottle filling and capping machine.

Choosing a supplier that provides after-sales support, spare parts, and technical guidance is crucial to minimizing downtime.

7. Future Trends in Bottle Filling and Capping Machines for Small and Medium-Sized Enterprises

Technological advances are making filling and capping machines more accessible to small businesses. Features such as IoT connectivity for performance monitoring, AI-based quality control, and fully modular designs will enable small and medium-sized enterprises to further improve efficiency and product consistency.

Conclusion

For small and medium-sized production lines, a bottle filling and capping machine is more than just a piece of equipment; it is a strategic investment in productivity, quality, and growth potential.

By automating key processes, SMEs can compete with large manufacturers, meet growing market demands, and ensure customer satisfaction through consistently high-quality products.

As technology continues to advance, the opportunities for SMEs to adopt automation will only grow, and now is the perfect time to invest in a machine that can transform your production line.

0