目录

ToggleAs cities grow vertically and infrastructure modernizes globally, the role of China elevator manufacturers has become increasingly central to the vertical transportation industry. With robust production capabilities, evolving safety compliance, and advanced customization options, Chinese manufacturers are influencing both domestic and international elevator markets. This article offers a concise, practical overview of what you need to know about the capabilities, trends, and practices of China elevator manufacturers.

Production Capabilities of China Elevator Manufacturers

China elevator manufacturers are responsible for over 60% of global elevator production. In 2023, China produced more than 1.2 million elevator units, supplying both the domestic and international markets. This capacity is supported by integrated production lines that include:

- CNC-machined elevator components

- Automated welding and laser cutting stations

- Specialized test facilities capable of simulating a variety of operational conditions for different building heights

- Independent assembly lines for traction, hydraulic, and home elevators

This manufacturing scale enables rapid production, cost control, and customization flexibility for small and large projects alike.

Safety Standards in China Elevator Manufacturing

Adhering to internationally recognized safety frameworks is fundamental for China elevator manufacturers seeking global market integration. In addition to Chinese national standards, many manufacturers comply with:

- EN81 (European elevator safety standards)

- ASME A17.1 (North American code compliance)

Relevant ISO standards that address elevator safety and environmental impact

Safety systems typically incorporated include:

- Speed monitoring devices and emergency brakes

- Load sensors and door obstruction detectors

- Emergency power systems ensuring safe cabin descent

- Enhanced structural protections for seismic and fire safety

Recent industry reports show that elevator quality assurance procedures have been significantly enhanced through stricter oversight and advanced testing protocols.

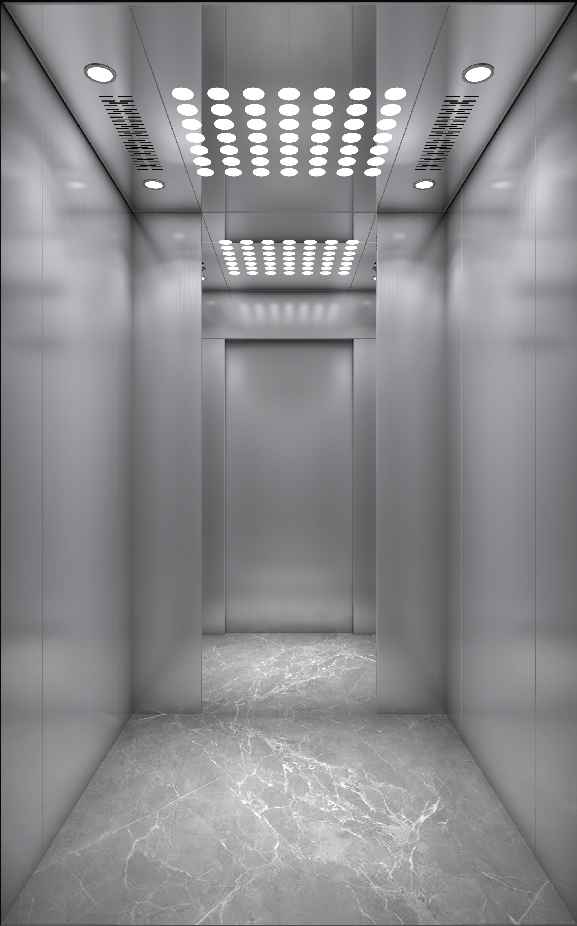

Customization Options by China Elevator Manufacturers

Buildings today require elevators that blend seamlessly with their architectural vision and functional needs. China elevator manufacturers provide wide-ranging customization, including:

- Cabin sizes designed to fit constrained spaces or oversized freight requirements (capacities up to 5000 kg)

- Speed ranges tailored from slower models ideal for residential buildings to high-speed elevators reaching up to 6.5 meters per second for commercial skyscrapers

- Interior design choices spanning stainless steel, glass panels, wood finishes, and antibacterial coatings

- User interfaces with multilingual voice guidance, touchscreen controls, and accessibility features

This adaptability allows Chinese manufacturers to address the requirements of various sectors such as healthcare, retail, residential, and logistics.

Energy Efficiency in China Elevator Manufacturing

Sustainability is gaining momentum across the elevator industry. Leading China elevator manufacturers now integrate energy-saving components to reduce both operational cost and environmental impact:

- Gearless permanent magnet synchronous motors

- Regenerative braking systems that return energy to building circuits

- LED cabin lighting with motion sensors

- Group control systems that optimize ride efficiency

These features can reduce elevator energy consumption by up to 35%, making them suitable for LEED-certified and eco-conscious projects.

Global Reach of China Elevator Manufacturers

Over the past decade, China elevator manufacturers have rapidly expanded their global footprint. Elevators made in China are now exported to over 130 countries, with major markets including Southeast Asia, the Middle East, Eastern Europe, and Africa.

Key factors behind this export success include:

- Competitive pricing for high-volume orders

- Growing reputation for safety and quality compliance

- Shorter lead times due to localized component sourcing

- Experience in public infrastructure tenders and B2B contracts

Most export-ready manufacturers offer multilingual technical documentation, third-party quality certifications, and remote support for installation and maintenance.

Smart Technology in China Elevator Systems

The adoption of intelligent systems is transforming elevator use and maintenance. Many China elevator manufacturers are now integrating digital features such as:

- IoT-enabled diagnostics and remote fault alerts

- Touchless control panels using voice or QR recognition

- Intelligent dispatch algorithms to reduce wait times

- Cabin monitoring via cloud-based data analytics

These smart features are especially in demand for airports, hospitals, office towers, and residential smart communities.

Conclusion

China elevator manufacturers have evolved into key players in global urban infrastructure. With massive production capabilities, commitment to international standards, and growing smart technology integration, they offer practical and scalable elevator solutions for projects of all sizes. For contractors, architects, and facility managers, understanding the strengths and considerations of working with Chinese suppliers is essential to successful elevator planning and deployment.

0