目录

ToggleIntroduction to Pre-Terminated FTTH Drop Patch Cord Solutions

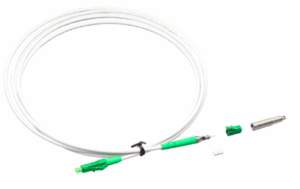

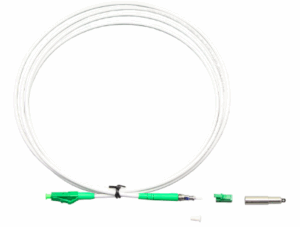

Pre-terminated FTTH Drop Patch Cords streamline fiber optic installations by providing fully assembled and tested cables with precision-fitted connectors straight from the factory. Unlike traditional field termination, which requires precision tools and highly trained technicians, pre-terminated solutions arrive ready for use with connectors that are factory-polished, tested, and sealed against contamination. This approach greatly improves installation efficiency and ensures consistent performance across all deployed links.

The demand for pre-terminated FTTH Drop Patch Cords has grown rapidly, particularly in residential fiber-to-the-home networks where reliability and quick deployment are essential. Studies from the Fiber Broadband Association indicate that pre-terminated solutions can accelerate installation projects by 30–50%, making them a preferred option for service providers.

Reduced Installation Time with Pre-Terminated FTTH Drop Patch Cords

Traditional field termination involves fusion splicing, connector assembly, and testing, processes that can take 30–60 minutes per connection point. In contrast, pre-terminated FTTH Drop Patch Cords allow installers to simply route the cable and plug in connectors, cutting installation time by up to 50%.

Key efficiency advantages include:

- Minimal Equipment Requirements

Installers no longer need fusion splicers, cleavers, or high-end inspection tools on site. This reduces capital expenditures for service providers by an estimated $15,000–$25,000 per installation team. - Reduced Labor Costs

Because field termination skills are not required, less experienced crews can perform installations. Average labor savings are approximately 20–30% per project. - Faster Rollouts

For large-scale FTTH deployments, pre-terminated cords enable a 40% increase in daily installations per team, allowing providers to scale networks faster.

This speed is particularly advantageous in dense urban rollouts and temporary event networks.

Improved Connection Quality and Reliability with FTTH Drop Patch Cord

The factory-controlled environment for pre-terminated FTTH Drop Patch Cords results in higher and more consistent connection quality than field-terminated alternatives.

- Superior Optical Performance

Connectors polished in controlled factory environments consistently deliver insertion loss under 0.2 dB and return loss exceeding 60 dB for APC types—essential for GPON networks that operate within a strict optical budget of 28 dB. - Minimized Contamination Risks

Dust and debris are responsible for nearly 80% of fiber optic failures. Pre-terminated cords ship with protective end caps, keeping connectors sealed until deployment to ensure pristine endfaces. - Higher Durability

Materials such as aramid yarn reinforcement and Low Smoke Zero Halogen (LSZH) jackets enhance the mechanical strength of these cords, allowing them to endure pull forces of up to 100 N without performance degradation.

These features together ensure long-term network reliability and reduced fault rates.

Lower Long-Term Maintenance Costs with FTTH Drop Patch Cord

Pre-terminated FTTH Drop Patch Cords not only simplify installation but also reduce ongoing maintenance expenses.

- Fewer Connector Failures

Studies show a 35% reduction in connector-related faults when using pre-terminated cords. - Simplified Troubleshooting

Standardized lengths and connector types (SC/APC, LC/APC) make it easy to replace cables during maintenance without requiring re-termination. - Improved Uptime

Ruggedized pre-terminated designs resist environmental stressors, keeping networks online even in challenging conditions. This translates into lower customer complaints and SLA penalties for service providers.

Versatility of Pre-Terminated FTTH Drop Patch Cords

Pre-terminated FTTH Drop Patch Cords are highly versatile and adaptable across a variety of installation environments.

In indoor residential installations, they are favored for their small diameter and bend-insensitive fibers (G.657A2), which support bend radii as tight as 7.5 mm without signal degradation. This makes them ideal for routing through narrow conduits and behind walls in multi-dwelling units (MDUs).

For outdoor or harsh environments, ruggedized versions with UV-resistant LSZH jackets and water-blocking gel offer protection against extreme temperatures ranging from –40°C to +85°C and crush forces up to 1000 N. These features ensure reliability in aerial, underground, and exposed installations. Temporary setups such as events or construction sites also benefit from the plug-and-play nature of pre-terminated cords, enabling rapid deployment and teardown with minimal tools.

Simplified Logistics and Inventory Management with FTTH Drop Patch Cord

Inventory management is more efficient when using pre-terminated FTTH Drop Patch Cords, as standardized lengths and connector types reduce storage complexity and improve project readiness. Providers can stock a limited range of cord lengths, such as 1 m, 5 m, 10 m, 20 m, and 50 m, to meet most deployment scenarios, reducing warehouse space needs by up to 25%. This streamlines procurement, minimizes lead times, and prevents costly stockouts during peak deployment seasons.

Conclusion

Pre-terminated FTTH Drop Patch Cords deliver measurable advantages in speed, reliability, and cost-effectiveness. Their factory-tested precision reduces installation time by up to 50%, minimizes field errors, and enhances long-term network performance. With superior durability and simplified logistics, these solutions are ideal for service providers seeking to scale FTTH networks rapidly while maintaining high standards of quality. Investing in pre-terminated patch cord solutions is a proven strategy for building robust and future-ready fiber networks.

0