目录

ToggleWhy Proper Design of Ground Anchor Bolts Is Critical

Ground anchor bolts are the unseen heroes in structural systems, providing the stability needed to withstand wind, seismic forces, and heavy loads. However, design flaws in these components can lead to costly failures, compromised safety, and legal liabilities. Avoiding common mistakes during the design phase is essential for property owners, engineers, and contractors aiming to ensure long-term structural integrity.

This guide highlights frequent errors in ground anchor bolt design and offers expert tips to avoid them.

Misjudging Load Requirements in Ground Anchor Bolt Design

Failing to Account for Dynamic and Static Loads

One of the most common mistakes is underestimating the forces that ground anchor bolts must endure. Many designs focus on static loads while overlooking dynamic factors like:

-

Wind uplift forces in tall structures.

-

Vibrations from machinery or traffic near the site.

-

Seismic activity in earthquake-prone regions.

To prevent failure, designers should consider all potential load scenarios and select bolts with adequate tensile and shear capacity.

Ignoring Soil Characteristics

The type of soil where the bolts are embedded plays a significant role in performance. Loose or sandy soils require different anchoring strategies compared to dense clay or bedrock. Failing to adapt the design to site-specific soil conditions can compromise holding strength.

Selecting the Wrong Materials for Ground Anchor Bolts

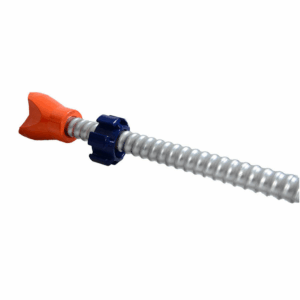

Overlooking Corrosion Resistance

Using standard steel bolts in environments prone to moisture or salt exposure accelerates corrosion. This oversight shortens the lifespan of the bolts and increases maintenance needs. For improved durability, designers should:

-

Specify stainless steel or hot-dip galvanized bolts for corrosive environments.

-

Consider epoxy-coated bolts for additional protection.

Not Matching Bolt Grades to Structural Needs

Choosing lower-grade bolts to reduce costs may lead to insufficient strength under high loads. Always align material grade with the structure’s design specifications and safety requirements.

Poor Detailing and Placement of Ground Anchor Bolts

Inaccurate Positioning During Design Phase

Improper spacing or misalignment of bolts can cause uneven load distribution. Common issues include:

-

Bolts placed too close to concrete edges, risking cracking.

-

Insufficient embedment depth, reducing pullout resistance.

To avoid these mistakes, use precise drawings and coordinate with installation teams to ensure accuracy.

Neglecting Edge Distance and Grouping Effects

Failing to maintain proper edge distances or placing multiple bolts too close together leads to concrete breakout or reduced anchoring efficiency. These factors must be incorporated into the initial design calculations.

Ignoring Long-Term Maintenance in the Design Process

Designing Without Accessibility in Mind

Bolts installed in hard-to-reach areas complicate inspections and maintenance. Design considerations should include:

-

Clear access points for visual and torque inspections.

-

Protective caps or coverings to shield exposed parts from the elements.

Failing to Plan for Future Retrofitting

Structures may require upgrades over time due to evolving codes or increased load demands. Incorporating flexibility for retrofitting in the original design can save significant time and costs later.

Best Practices to Avoid Design Mistakes in Ground Anchor Bolts

Conduct Thorough Site Assessments

-

Analyze environmental factors such as humidity, temperature fluctuations, and seismic risks.

-

Perform soil testing to guide bolt type and embedment depth decisions.

Engage Multidisciplinary Collaboration

Involve engineers, architects, and contractors early in the design phase to identify potential conflicts or challenges before construction begins.

Use Advanced Design Tools and Standards

Leverage structural analysis software and adhere to international codes like ACI or Eurocode for accurate and compliant designs.

Consequences of Poor Ground Anchor Bolt Design

Ignoring these critical design elements can lead to:

-

Premature bolt failure under stress.

-

Costly structural repairs or replacements.

-

Legal action due to non-compliance with building codes.

Proactive design measures ensure the structure’s longevity and safety while minimizing future risks.

Conclusion: Invest in Smart Design for Reliable Ground Anchor Bolts

The design phase is your first and best opportunity to secure the performance of ground anchor bolts. Avoiding common mistakes—like misjudging loads, selecting inappropriate materials, and neglecting long-term considerations—ensures that your structure remains safe and durable for decades.

For property owners and builders, collaborating with experienced professionals and prioritizing quality over short-term savings is the key to avoiding catastrophic failures and unnecessary expenses.

0